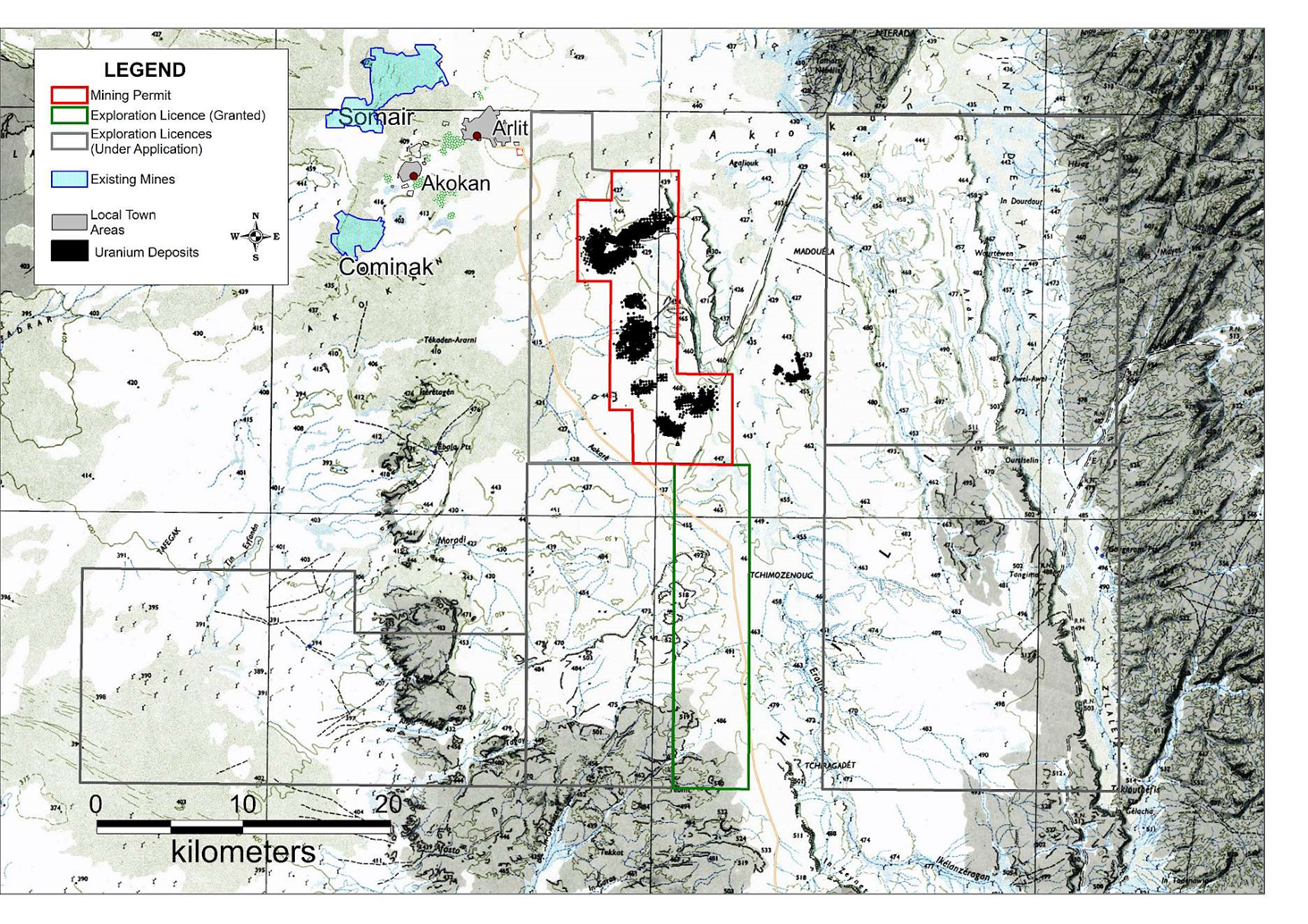

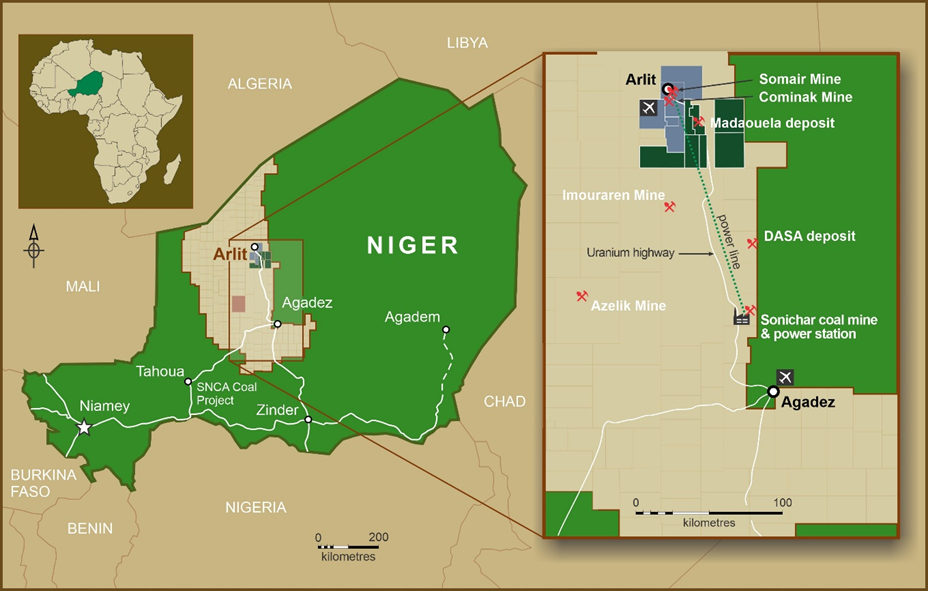

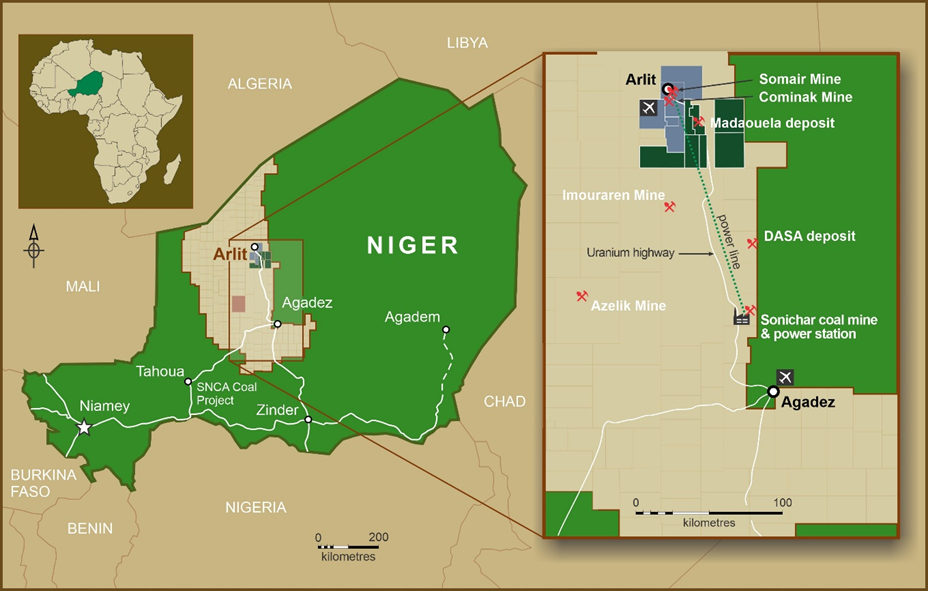

The Project is situated in the Agadez region in the northern part of the Republic of Niger adjacent to ORANO SA’s operations of SOMAIR and COMINAK and benefits from the existing infrastructure and an experienced local uranium mining labour force. GoviEx operates the Project and holds an 80% interest of the Nigerien operating company COMIMA with the remaining 20% held by the Republic of Niger, of which 10% represents a free-carry interest. The Project also includes a series of other deposits, not included in the 2022 FS, that are anticipated to be mined by either open pit or underground methods.

The Republic of Niger is currently the 7th largest producer of uranium in the world and was the largest supplier of U3O8 to Europe in 2022, accounting for approximately a quarter of total imports. The project therefore is advantageously placed in a mining friendly jurisdiction and currently has all major permits required for development.

Figure 1: GoviEx land holdings - Madaouela Uranium Project

Figure 2: Plan view of the Madaouela Uranium Project

Mining

Mining operations for the Project are planned to be initially based on standard truck and shovel open pit mining for the Miriam deposit at a planned rate of 1 Mt per annum of ore feed to the process plant.

The M&M and MSNE-Maryvonne deposits are planned to be mined as two independent underground room and pillar operations. M&M is to be mined first following completion of the Miriam open pit operation, with MSNE-Maryvonne mined after M&M.

At both underground operations the mine development and ore production operations are planned to be by conventional drill and blast. Mined ore is expected to be fed onto a conveyor system via feed breakers. Run of mine ore will be sorted at the portal by X-ray fluorescence ("XRF"), and post sorted ore is planned to be trucked to the process plant at a rate of 1.0 Mtpa.

Processing

The process plant is designed around two stage acid leaching to maximised uranium and molybdenum recovery whilst reducing overall acid consumption. Plant feed is designed at 1 Mtpa, with ore initially crushed before milling. The Feasibility Study has been moved away from SAG milling in the comminution circuit due to the introduction of the two VeRo Liberator mills as a replacement in order to reduce operating and capital costs associated with the comminution process as well as improving total power required.

Milled ore is planned to be leached using sulphuric acid to extract the uranium and molybdenum into solution, with the molybdenum to be removed from the solution by continuous flow Ion Exchange, rather than cartridge approach to reduce operating costs, with precipitation of the molybdenum to produce molybdenum tri-sulphide (MoS3). The Project is designed to produce triuranium octoxide (U3O8) through industry standard ammonium diuranate (ADU) and calcination.

The table below shows the proposed capital requirements of the Project's initial development and remaining life of mine sustaining capital costs. The majority of the sustaining costs are related to the development costs associated with the M&M and MSNE-Maryvonne deposits.

Initial capital costs are forcasted to be USD 342.7m, and includes pre-stripping of the Miriam deposit.

Table 1- Project initial and sustaining capital

| USDm |

Initial Capital |

Sustaining Capital |

| Open Pit |

46.1 |

2.7 |

| Underground |

- |

218.6 |

| Processing |

242.4 |

3.1 |

| Tailings |

14.8 |

7.8 |

| Infrastructure |

28.6 |

36.7 |

| Water management |

6.0 |

7.6 |

| Owner costs |

4.8 |

- |

| Total construction costs |

342.7 |

276.6 |

*A contingency of 10% is included in the capital figure quoted above.

Based on a uranium price of USD 65/lb U3O8 and molybdenum price of USD 11/lb Mo over the life of mine, the Project is forecast to produce USD 673 million in free cash flow, including capital expenditure, and is forecast to produce an annual average of USD 82.6 million EBITDA.

Table 2- Project unit Operating Costs

| |

USD/t Process |

USD/lb U3O8 |

| Open Pit Mining |

20.76 |

9.13 |

| Underground Mining |

44.01 |

16.04 |

| Total Mining* |

38.07 |

14.50 |

| Processing |

35.75 |

13.62 |

| SG&A |

9.29 |

3.53 |

| Royalty Tax |

12.06 |

4.59 |

| Total Operating Costs |

95.57 |

36.40 |

| Total Operating Costs net of Mo reserve case |

93.99 |

35.80 |

| Total Operating Costs net of Mo all resource case |

88.01 |

33.52 |

*Weighted average between open pit and underground mining costs

The Madaouela Project contains molybdenum mineralisation in both the Miriam open and the underground mines, and this saleable by-product results in additional revenue to support the development of the project and its cashflows.

It is of note that the process plant has been designed and costed for the recovery of molybdenum for the life of the mine. While molybdenum reserves are defined for the Miriam open pit and the initial mining period in the M&M, the molybdenum resources have not been classified for the rest of M&M and MSNE, but the financial model continues to incur the associated costs with its recovery. The table below provides and estimate of the impact of inclusion of the non-M&I molybdenum mineral resources as a sensitivity.

Table 3- Molybdenum by-product credits

| |

USD/t Process |

USD/lb U3O8 |

| Mo Mineral Reserve Case |

1.58 |

0.60 |

| Mo All Resources Case |

7.56 |

2.88 |

The table below provides a sensitivity of the projects NPV and IRR% at a range of uranium prices and is based on the Mineral Reserves only, for both uranium and molybdenum.

Table 4- NPV and IRR sensitivity Mineral Reserve Case

| Price (USD/lb U3O8) |

NPV8% |

IRR% |

| 60 |

41 |

9.7% |

| 65 |

120 |

12.7% |

| 70 |

199 |

15.5% |

As noted above the process plant has been designed and costed for the recovery of molybdenum for the life of the mine. While molybdenum reserves are defined for the Miriam open pit and the initial mining period in the M&M, molybdenum resources have not been classified for the rest of M&M and MSNE, but the financial model continues to show the associated costs with its recovery. The tabel below provides an estimate of the impact of inclusion of the non-M&I molybdenum mineral resources as a sensitivity.

Table 5- NPV and IRR sensitivity including addition Mo resources

| Price (USD/lb U3O8) |

NPV8% |

IRR% |

| 60 |

61 |

10.4% |

| 65 |

140 |

13.3% |

| 70 |

219 |

16.0% |

A number of potential optimisations are not included in the current study which will be assessed in the next stage, namely:

- Use of a Power Purchase Agreement ("PPA") for the supply of renewable energy for the project. The FS assumes a USD 14.3 million capital investment at the start of the project to provide a solar hybrid power plant to ensure power stability. Now that the power load is finalised, the next stage can include negotiations for PPA contracts whilest ensuring the Levelised Cost of Electricity (LOCE) is improved.

- The FS assumes that the Miriam mining fleet would be purchased new as the conservative option, however given the relatively short life of the Miriam deposit, and assessment of second hand/refurbished open pit mining equipment was undertaken. This study indicated that savings between 30 and 60% could be achievable by using second hand or refurbished open pit mining equipment. The initial mining equipment capital cost is currently planned at USD 26.4 million.